Industrial growth in India demands precision-engineered components that can withstand extreme conditions. Whether you’re building infrastructure, manufacturing automobiles, or assembling heavy machinery, the quality of your fasteners directly impacts safety and longevity. That’s where we come in. At Rajat Exports, we’ve spent years perfecting our craft as trusted bolt manufacturers in India, delivering products that meet international standards while staying true to our commitment to excellence.

What Sets Us Apart in the Fastener Industry

The fastener market is crowded, but not all manufacturers deliver the same value. Here’s what makes our approach different:

Engineering That Goes Beyond Basics

We don’t just produce bolts—we engineer solutions. Our manufacturing facility uses German CNC machines and automated threading systems that achieve tolerance levels of ±0.05mm. Every hex bolt, anchor bolt, or customized fastener goes through multiple quality checkpoints before leaving our factory floor.

Our metallurgy team works with IS 1367, ASTM A325, and DIN 931 standards depending on your application needs. Whether you need Grade 8.8 high-tensile bolts for automotive assemblies or marine-grade stainless steel fasteners for coastal projects, we’ve got the technical expertise to deliver exactly what your project demands.

Product Range Built for Real-World Applications

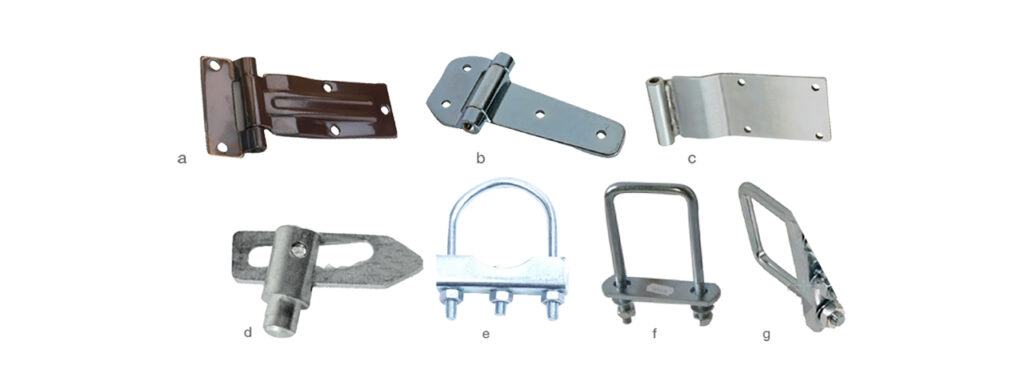

We manufacture over 2,000 fastener variants across different categories:

Standard Configurations: Hex head bolts, carriage bolts, flange bolts, and eye bolts form our core product line. These are available in sizes from M6 to M100, with threads cut to perfection.

Specialized Solutions: U-bolts for pipe mounting, foundation bolts for heavy equipment, and socket head cap screws for precision machinery are manufactured based on detailed engineering drawings.

Custom Manufacturing: Got unique specifications? Our design team collaborates with yours to create fasteners that fit your exact requirements—custom lengths, special coatings, non-standard thread pitches, or unusual head configurations.

Industries We Serve Across India and Beyond

As established bolt manufacturers in India, we’ve built partnerships across multiple sectors:

Construction Projects: From metro rail projects to flyover constructions, our structural bolts are holding together some of India’s most ambitious infrastructure developments.

Automotive Manufacturing: Tier-1 suppliers trust us for critical fasteners used in engine assemblies, chassis components, and safety systems. Our bolts meet the stringent requirements of both domestic and export-oriented automobile manufacturers.

Energy Sector: Power plants, wind turbine installations, and oil refineries use our high-grade alloy steel bolts designed to perform under thermal stress and corrosive environments.

Agricultural Equipment: Tractor manufacturers and farm equipment producers rely on our cost-effective yet durable fastening solutions that can handle rural India’s challenging operating conditions.

Defense and Railways: Government projects demand compliance and consistency. Our certifications and quality documentation meet the rigorous standards required for these critical applications.

Quality Control: The Foundation of Everything We Do

Visit our Ludhiana facility, and you’ll see why clients consider us reliable bolt manufacturers in India. Our quality process isn’t an afterthought—it’s integrated into every production stage:

Raw Material Verification: We source certified steel from SAIL, Tata Steel, and JSW. Each batch comes with mill test certificates, and our in-house spectrometer verifies composition before materials enter production.

Process Monitoring: Real-time monitoring during forging, threading, and heat treatment ensures consistency. Our furnaces maintain temperature accuracy within ±5°C, critical for achieving precise hardness ratings.

Coating Excellence: Whether you need zinc plating, hot-dip galvanizing, or Dacromet coating for corrosion resistance, our surface treatment facilities deliver uniform coverage and thickness.

Final Inspection: Every production lot undergoes tensile testing, proof load testing, and hardness checks. We maintain detailed QC records that are available for client audits.

Why International Buyers Choose Us

Being among the leading bolt manufacturers in India means competing globally. We’ve successfully established our presence in 32 countries across Asia, Europe, the Middle East, and Africa. Here’s why international buyers keep coming back:

Competitive Pricing Without Quality Compromise: Our efficient production systems and strategic raw material sourcing allow us to offer prices that are 15-20% more competitive than European manufacturers, without cutting corners on quality.

Export Documentation Expertise: We handle all export paperwork—from commercial invoices to certificates of origin. Our logistics team coordinates with freight forwarders to ensure smooth customs clearance at destination ports.

Flexible Order Quantities: Whether you need 500 pieces for a trial order or 50,000 pieces for large-scale projects, we accommodate orders of all sizes without minimum order value restrictions for established clients.

Sustainable Manufacturing Practices

Modern manufacturing carries environmental responsibility. As conscious bolt manufacturers in India, we’ve implemented several green initiatives:

Our induction heating systems consume 30% less energy compared to traditional furnaces. We’ve installed solar panels that generate 150 kW, covering a significant portion of our daytime power needs. Scrap metal from our cutting operations is 100% recycled back into the production chain, reducing waste to near-zero levels.

Water used in our quenching process goes through a closed-loop recycling system. We’ve also switched to water-based rust preventive oils that are biodegradable and safer for workers.

Custom Engineering: Solving Unique Challenges

Sometimes standard catalog products don’t fit. That’s when our custom engineering capabilities become valuable. Recently, a wind energy company approached us with a challenge—they needed extra-long foundation bolts (3.5 meters) with specialized threading that could handle cyclic loading. Our team developed a solution using micro-alloyed steel with specific heat treatment protocols. The result? Bolts that exceeded their fatigue life requirements by 40%.

Another client in the marine industry needed stainless steel bolts with Xylan coating for underwater applications in salt water. We collaborated with coating specialists to develop fasteners that showed zero corrosion after 5,000 hours of salt spray testing.

These success stories reflect our approach as bolt manufacturers in India who see beyond standard production—we solve problems.

Partnership Approach: More Than Just Supply

We believe in building relationships, not just completing transactions. When you work with us:

Technical Support: Our engineers are available to discuss material selection, grade recommendations, and design optimization. We’ve helped clients reduce costs by suggesting alternative specifications that meet their performance needs.

Inventory Management: For high-volume users, we offer vendor-managed inventory programs. We maintain buffer stocks at our warehouse, ensuring you never face production delays due to fastener shortages.

Transparent Communication: From quote to delivery, you’ll have a dedicated account manager who keeps you updated. We respond to inquiries within 4 hours during business days.

Future-Ready Manufacturing

The fastener industry is evolving. We’re investing in tomorrow’s capabilities today. Our new facility expansion will add fully automated production lines with robotic material handling. We’re also implementing AI-based quality inspection systems that can detect surface defects invisible to the human eye.

Training is continuous for our workforce. Last year, 85% of our shop floor employees completed skill upgradation programs in advanced manufacturing techniques and quality systems.

Getting Started Is Simple

Need fasteners for your next project? Here’s how we work together:

Step 1: Share your requirements—drawings, specifications, or just a description of what you need. We’ll respond with technical feasibility and quotation within 24 hours.

Step 2: For custom or critical applications, we’ll send samples for your approval before starting bulk production.

Step 3: Once approved, we’ll schedule production and keep you informed about progress. Our average production lead time is 2-3 weeks for standard orders.

Step 4: We arrange shipping to your doorstep—whether that’s a factory in Chennai or a construction site in Dubai.

Why Quality Fasteners Matter More Than You Think

A bolt might cost just a few rupees, but its failure can cost millions. In 2019, a bridge collapse investigation revealed that substandard fasteners were a contributing factor. In automotive recalls, faulty bolts have caused safety concerns affecting thousands of vehicles.

Choosing reliable bolt manufacturers in India isn’t about finding the cheapest supplier—it’s about finding partners who understand that your reputation depends on the components you use. When a crane operator trusts the lifting eye bolt, when a family drives on a highway supported by our anchor bolts, when a power plant runs continuously with our flange bolts holding critical assemblies—that’s when we know we’ve done our job right.

Let’s Build Something Together

At Rajat Exports, we’re more than manufacturers—we’re problem solvers, quality advocates, and partners in your success. With three decades of experience, modern manufacturing capabilities, and an unwavering commitment to excellence, we’ve earned the trust of over 800 clients across industries.

Whether you’re an OEM looking for consistent quality, a project contractor needing bulk supplies, or an international buyer seeking competitive pricing, we have the capability and capacity to meet your needs.

Ready to experience the difference? Contact our team today. Let’s discuss how our expertise as premier bolt manufacturers in India can contribute to your project’s success. Because when you choose quality fasteners, you’re not just buying bolts—you’re investing in safety, reliability, and peace of mind.